After having completed my scratchbuilt Class 17 Clayton in 2005, and being something of a glutton for punishment, I always thought I’d like to have a go at a Class 15 as well someday.

January 2007, despite having a pile of flat, unfinished or temporarily-abandoned modern image locomotive, wagon, carriage and van kits, it seems to be as good a time as any to make a start on something totally new :)

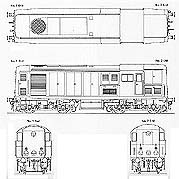

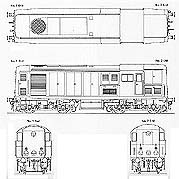

1. First steps are to find visual reference photos in books and on the web and scan, reduce and print a copy of a 4mm scale drawing to 3mm scale.

|

|

The drawing will be the blueprint for measuring dimensions as well as being the template for cutting components from sheet brass and plastikard, so it’s important to get it scaled right;

- Multiple copies were printed out from Adobe Photoshop at a range of different pixels/cm resolutions. Key standard datum such as gauge, buffer head distance and buffer to railhead were then measured on each and compared with dimensions measured with digital callipers from other plans and other models.

- The standard datum I can always rely on is that wheel treads are 14.2mm apart, but I cannot be sure that other dimensions either of the 4mm plan, or of the models I am measuring against were accurate to start with, so it's a bit of a compromise.

|

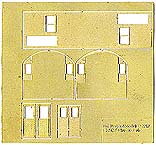

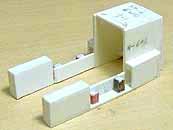

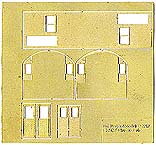

2. Closer examination of the drawing and photos shows that the only complex curves are at the top ends of the nose sections, and these should be possible to shape out of modelling putty. Superstructure construction will be helped by the cab being available in 3mm scale as a brass etching from Bill Bedford models - bought a few years ago more out of curiosity than any particular desire at the time to build a class 15, but from such little impulse purchases grand designs (or delusions!) can grow.

However, from measuring against my plan I am a little suspicious of the etching, although the roof height is about right, the cab fronts do seem to be a little on the narrow side.

These etchings are one-offs, produced individually on-demand as reductions of 4mm scale etches - so you just have to be thankful for what you can get...

|

|

|

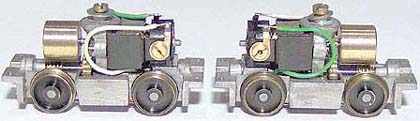

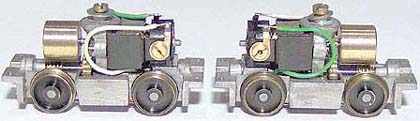

3. Although the wheelbase of the 12mm gauge Mike Chinery motor bogies is a little short by about 1.5 mm (or 6 inches in the real world), they are small enough to fit inside the restricted space in the nose sections and still give enough “swivel” to negotiate sharp curves, or so the drawing would suggest, so I am willing to compromise on wheelbase.

|

4. I have a cunning plan…

4. I have a cunning plan…

|

The superstructure and the chassis will be separate units. The chassis will consist of a plasikard plate with mounting holes cut for the Chinery bogies and longitudinal reinforcing sections to prevent bowing. The bogie sideframes will be scratchbuilt and utilise details cut from scrap BTTB TT 1:120 loco sideframes. The body will consist of the Bedford etched brass cab and nose sections with plasikard sides and rolled brass tops. Detailling such as vents, doors etc... will either come from the 3SMR Diesel Details brass stamping or be scratchbuilt. Nose ends will be scribed and bent brass or plastikard and the end tops shaped from model filler.

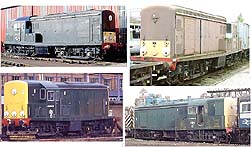

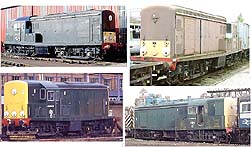

She will be painted as a representation of (D)8226 in the condition she was when withdrawn on Saturday 27th March 1971: An unusual combination of dual-tone Brunswick green livery with full yellow ends; BR double-arrow logo and Transport font numerals with the “D” prefix removed.

(D)8234 as station pilot at Liverpool Street sometime in the late 1960's showing exactly this livery combination. An interesting detail is that she has had the TOPS data panel transfer applied to the cabside, but these ahesive vinyl patches were only ever manufactured with BR blue colour backing, so there is a BR blue patch on an otherwise Brunswick green loco...

|

|

|

Inspiration

If mine turns out even halfway as good as this superb build of the 4mm Dave Alexander kit, I will be well pleased.

|

5. Cutting the first sod. Sunday 25th February 2007. The

chassis footplate has been cut from 1.5mm gauge sheet plastikard.

|

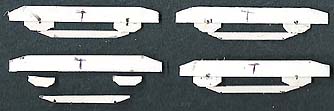

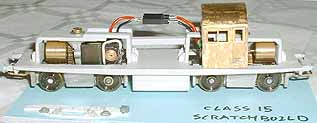

6. The rolling chassis; footplate, uprights and bogie mounting plates are cut from 1.5mm gauge sheet. To prevent wear and the mounting holes enlarging over time, the bogie mounting plates have a small shim of brass fitted to the underside that the bogie mounting then mates up against. Bracing, bufferbeam, solebars etc.. are cut from 1mm gauge sheet.

|

|

|

7. Unfortunately my suspicions of the etch dimensions have been borne out, the cab is about 2mm too narrow when soldered up. This presents two choices:

1. Accept the difference and live with the fact that the nose ends are also therefore 2mm too narrow and that nearly 2mm will need shaving off the solebars so that the footplate does not look ridiculously wide.

2. Cut the cab assembly in half down the middle and solder in a 2mm strip of brass.

Option 2 is going to have to be the way to go...

|

|

|

8. The bogie sideframes are constructed from Plastikard sections. Detail will be provided by old BTTB plastic diesel bogie sideframes; the components individually cut off, shaped and then filed down; 8 axlebox covers, 4 sand boxes, 8 large coil springs, 8 medium coil springs, 8 dampers and 4 brake resevoirs.

This might take a while... :-(

|

|

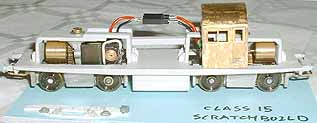

9. The chassis is now fully running and weighted with lead in the central fuel tank. Simple bar couplings made from brass wire have been soldered to the whitemetal bogies and 3mm Society whitemetal BR standard loco buffers fitted. The Chinery bogies are continuously wired with a plug and socket and it pulls a respectable number of wagons and runs smoothly through reverse curve pointwork. There'd even be room in the middle for a DCC decoder (hmmm...). Only one sideframe has been half-completed so far though, they really are a very tedious job.

Photo by Dave Southam at the 3mm Soc AGM May 2007.

|

|

|

10. Christmas 2007. Progress had been a bit slow, but the end of the year saw a burst of activity with the bogie sideframes completed and mounted. The cab has been split with a slitting disc, moved outwards and re-soldered with strips of brass.

|

|

|

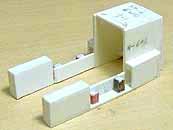

No 2. end superstructure and cab mounting constructed from 1mm sheet plastikard.

|

4. I have a cunning plan…

4. I have a cunning plan…