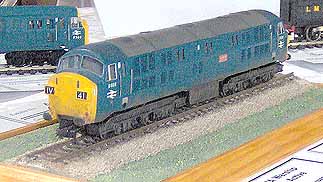

North British "Warship" - D600 Active

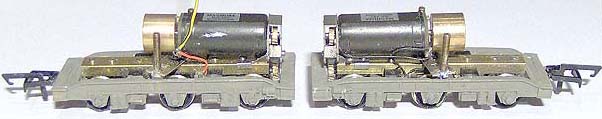

This etched nickel-silver Worsley Works kit is very basic, what you see in the pic below is all you get. Allen of Worsley Works describes his products as "scratch aids", so motorisation and fittings always require a certain amount of initiative, but I do have one or two ideas....

9. The sideframes have now been glued to the Bullant bogies using Araldite and a framework built up around them from Plastikard to give both rigidity and a mounting for the new style Hornby OO couplings; both smaller and therefore less obtrusive, as well as backwards-compatible with, the original Tri-ang couplings on the majority of my stock.

Plus two pictures also taken at the AGM by Geoff Helliwell

|

|